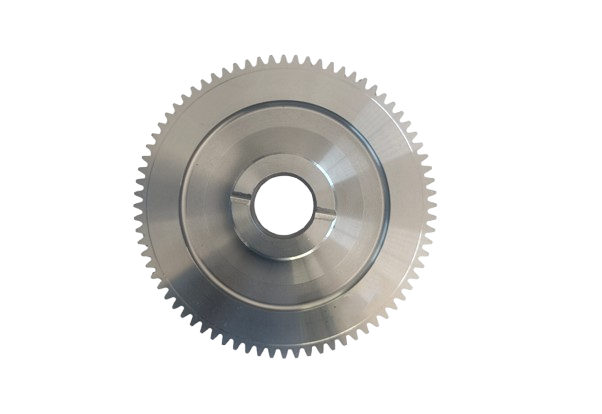

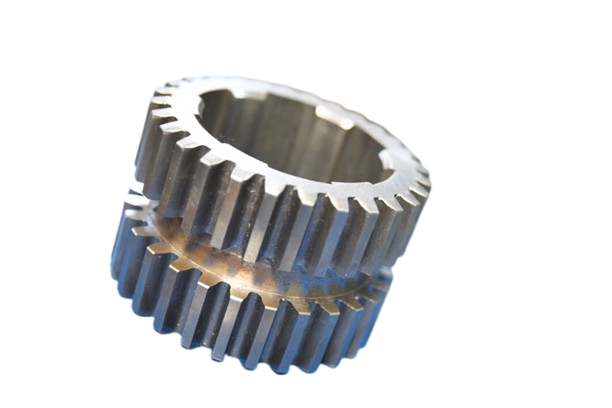

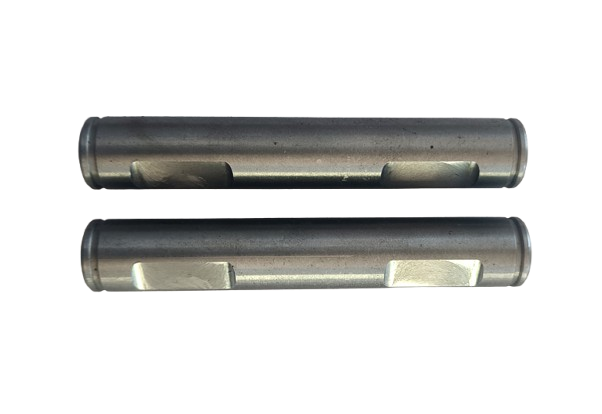

Carburizing

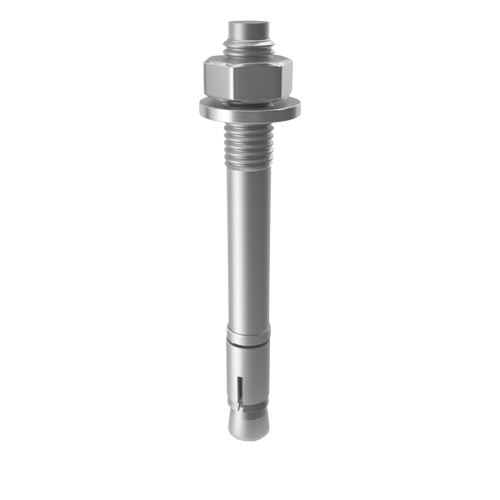

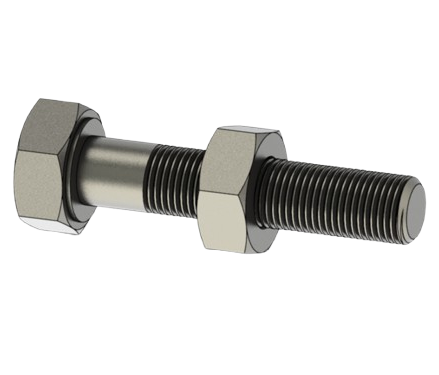

Hardening and Tempering

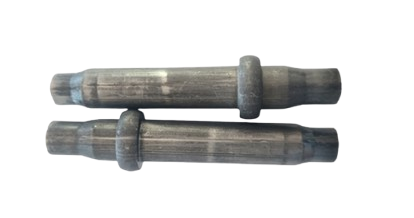

Annealing, Normalizing and Stress Relieving

To Get a Quote:

Call us now at +91 90074 37303 or

Email us at evolveheat@gmail.com

The key to world-class Heat Treatment is "Process Control".

Process Control makes it possible to attain Desired Results repeatedly with Minimum Deviation.

We are committed to provide High Quality Controlled Atmosphere Heat Treatment Service at competitive prices.

To Get a Quote:

Call us now at +91 90074 37303 or

Email us at evolveheat@gmail.com

In-House Metallurgical Lab

In-House Lab facility for sample preperation, hardness testing, case-depth determination and microstructure analysis

SCADA Supervisory Control

Ensures real time process monitor and control and data tracebility to achive desired results repeatedly

Controlled Atmosphere

State of the art Sealed Quench Furnace provides protective environment to eliminate Scaling, Decarb and minimise Distortion

On Time Delivery with Reports

Proper Process Planning to ensure on time delivery with Time Temperature Graphs and Metallurgical Analysis Reports